Don't miss the next drop

Omega 502

- Launch Year: 1956

Specifications | |

|---|---|

Brand | |

Caliber Number | 502 |

Production Start Year | 1956 |

Production End Year | 1960 |

Lignes | 12.5″ |

Diameter | 28.5mm |

Height | 7.45mm |

Power Reserve | 46 hours |

Frequency | 19,800 vph / 2.75 Hz |

Jewel Count | 17 |

Escapement | Swiss Lever |

Anti-Shock Device | Incabloc |

Hand Count | 3 |

Manufacture Region | Switzerland |

Functions | Time-only, Date (variant) |

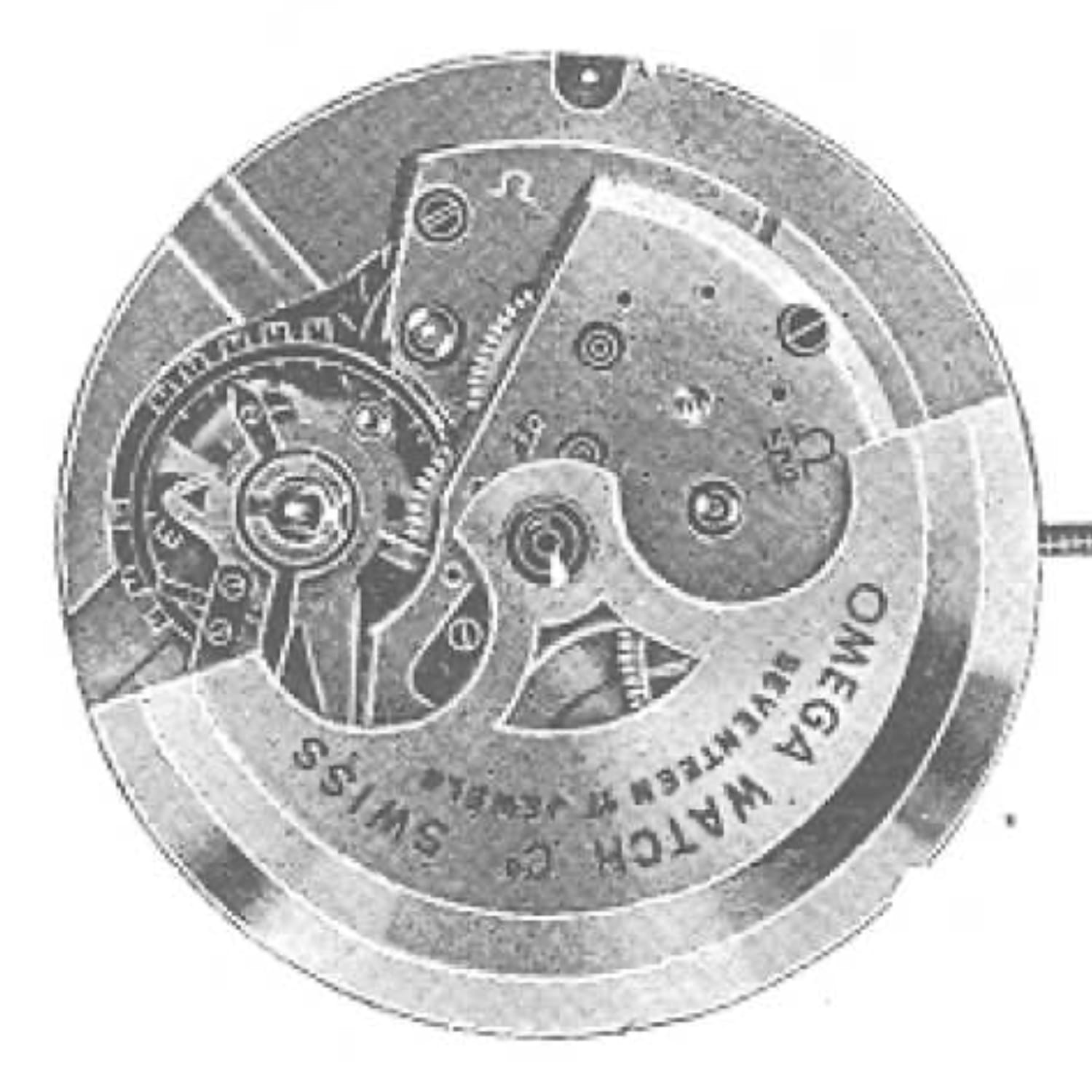

Omega 502 Description

The Omega Cal. 502 is a mid-range, full-rotor automatic movement that represents Omega’s refinement of their early robust caliber family during the mid-1950s. Designed specifically as a “US export” version responding to tariff restrictions on imported watch movements, the 502 remains relatively understated in horological circles compared to legendary Omega movements like the 321, yet it served important watches across multiple Seamaster and Constellation references. With a respectable 46-hour power reserve and solid 17-jewel construction, the 502 balanced durability with cost-effectiveness, making it a workhorse caliber for everyday professional watches of the late 1950s.

HISTORY & DEVELOPMENT

The Omega Cal. 502 emerged in 1956 as a strategic variant engineered to navigate early Cold War-era trade regulations. During this period, the US imposed higher import tariffs on finished watch movements, incentivizing manufacturers to import unfinished movement blanks (ebauches) for completion stateside. The 502 was developed directly from the Cal. 500 platform, sharing much of its base architecture while introducing refinements suited to American market specifications.

The movement first appeared in Seamaster models and early Constellation variants aimed at North American distribution, particularly through the influential Norman Morris agency, which served as Omega’s exclusive US distributor from the 1930s through 1980. The 502 remained in production until approximately 1960, with documented examples appearing in watches shipped to US Army exchange (PX) facilities, a valued distribution channel for Omega during this era.

While overshadowed by higher-complication movements of the same period, the 502 established itself as a reliable platform for dress sport watches, consistently earning favorable feedback from watchmakers for straightforward serviceability and robust jeweling. Its design philosophy reflected Omega’s post-war commitment to integrating lessons learned from military chronometer production with commercial practicality.

TECHNICAL DETAILS

Winding System and Architecture

The Cal. 502 employs a full-rotor automatic winding mechanism, marking it among Omega’s first unidirectional rotor designs to achieve 360-degree continuous winding without the limitations of earlier bumper-wind systems. The rotor operates bidirectionally, efficiently converting wrist motion into mainspring tension across a wider range of movement patterns. This represented a significant step forward from the limited-swing rotor designs of the 1940s.

Regulation and Timing

The movement features a free-sprung balance wheel regulated by a standard regulating index (not a swan-neck regulator as found in contemporary Cal. 501 variants). At 19,800 vibrations per hour, the 502 operates at a conventional beat rate that proved reliable for general timekeeping across diverse climates and wear conditions. The 49-degree lift angle is relatively efficient, allowing accurate impulse delivery to the balance without excessive energy expenditure.

The 46-hour power reserve provides genuine practical utility, allowing the watch to be removed on Friday evening and reliably resumed Tuesday morning with acceptable timekeeping. This reserve is adequate for watches worn regularly but not obsessively wound.

Construction and Finishing

With 17 jewels strategically placed at bearing points, the 502 receives moderate finishing typical of Omega’s mid-range movements. Jeweling includes the barrel arbor, center wheel, third wheel, escape wheel, and balance wheel, while the pallet arbor remains unjeweled, a cost-conscious choice common across the era. The movement features an Incabloc anti-shock system protecting the balance staff from shock damage, a practical feature for a movement intended for active-wear sport watches.

Finishing reflects straightforward Omega standards: brushed steel components with selective polishing on visible elements like the rotor and balance cock. The movement lacks the elaborate Genève striping reserved for chronometer-certified calibers, but surfaces are adequately prepared and free from crude tool marks.

Engineering Context

The 502 sits firmly within Omega’s post-war automatic philosophy, emphasizing full-rotor efficiency over the earlier bumper-wind systems. It shares architectural DNA with the slightly earlier Cal. 470 and 471 family, inheriting proven solutions for mainspring, train wheel, and escapement geometry. This backward compatibility allows significant parts sharing with related calibers, a consideration that benefited both watchmakers and collectors decades later when service parts became scarce.

PARTS INFORMATION & DIAGRAMS

Show Image

The Cal. 502 shares substantial parts compatibility with its immediate family, particularly the Cal. 500, 501, 503, and 504 variants. The base ebauche originated from the Cal. 470 platform, meaning several structural components (barrel, center wheel bridge, escape wheel arbor) transfer across variants.

Commonly Replaced Components

- Mainspring: Metric width 1.2 mm, strength 0.1 mm. Sourced identically across Cal. 470, 500, 501, 502, 503, 504, 505.

- Balance staff: Subject to wear at the pivots, particularly if the Incabloc shock spring has engaged. Requires precise truing after replacement.

- Pallet fork: Wear to the jeweled pallet stones is common after 60+ years. Replacement maintains accurate impulse geometry.

- Hairspring: Free-sprung balance designs rarely require hairspring replacement unless physical damage occurred, but hairspring cleaning during servicing is standard.

- Canon pinion: Center wheel assembly that drives the minute hand. Rarely replaced unless stripped.

- Rotor and rotor bearings: The rotor arbor pivot (the point bearing the weight of the rotor) experiences characteristic wear. Some watchmakers replace only the bearing, others the complete rotor assembly.

Parts Sourcing

Omega 502 complete movement parts on eBay

Omega 502 balance complete on eBay

Omega 502 mainspring vintage watch on eBay

Omega 502 pallet fork on eBay

Parts marked “470 family” or “500 series Omega automatic” typically fit the 502 with verification of bridge geometry and spring tensions.

IDENTIFICATION & MARKINGS

Locating the Caliber Number

The caliber number “502” appears engraved on the balance cock (the bridge spanning the balance wheel and hairspring assembly), typically on the upper surface where it’s visible upon removing the caseback. This location is consistent with Omega standard practice for movements of this era.

Distinguishing Features

- Rotor design: The full rotor bears Omega’s distinctive radial segmentation pattern and includes the Omega logo. The rotor operates continuously without mechanical stops.

- Balance cock engraving: Clean, single-line engraving, never stamped. May include additional service marks or small jeweler’s marks from previous repairs.

- Bridge geometry: The 502 uses the same barrel bridge as the 500 and 501 but differs from these calibers in regulation method and specific component heights.

- Jewel count: Distinctly marked “17” somewhere on the movement, typically on the balance cock or main plate edge.

Service History Indicators

Watches from the 1950s commonly show previous service marks: small tool marks on the balance cock, replaced screws of slightly different finish, or rotor bearing wear that produced a light copper shine around the rotor arbor. Distinction between normal wear and inferior service requires examining screw quality, bridge surface tool marks, and jewel positioning consistency.

RELATED CALIBERS

| Related Caliber | Key Difference |

|---|---|

| Cal. 500 | Base caliber; 502 is regulator variant for US market |

| Cal. 501 | Swan-neck regulator; improved regulation stability |

| Cal. 503 | Variant of 502 with modified date complication |

| Cal. 504 | Chronometer-certified variant; enhanced finishing |

| Cal. 505 | Later evolution with refined geometry |

The 500 series represents Omega’s first full-rotor automatic family, established following the success of the earlier Cal. 470/471 pioneers. Each variant addressed specific market requirements, tariff conditions, or accuracy certifications without fundamentally altering the underlying ebauche architecture. The 502’s role as a “bridge” caliber, optimized for US market constraints while maintaining Swiss-standard durability, makes it a particularly interesting case study in mid-century trade policy’s impact on horological engineering.